BLOG

BALLAST IN AGRICULTURAL VEHICLES

USE OF BALLAST

GUIDANCE ON THE USE OF SOLID LASTRE AND LIQUID LASTRE

The traction, or tensile force that a tire can exert, is proportional to the weight it loads. The greater the load on a tire, the more traction force it exerts on the ground. This load must always respect the ratio of internal air pressure versus incident weight per tire - each incident load has a corresponding internal air pressure. This meets the standards in the tables of the Latin American Tire and Tire Association (ALAPA).

The way to ensure traction and reduce skating is to add weight to the tractor in order to obtain a good weight X power ratio (consult the equipment manufacturer for details). This weight is called ballast.

The ballast can be solid - metal weights placed on the wheels - or liquid, which is done by replacing part of the volume of air in the tires with water. Normally, antifreeze additives can be used to prevent freezing of water in tires where external temperatures are very low. In tropical countries, only water is used for liquid ballast.

Whenever possible, the use of solid ballast is recommended instead of liquid ballast. This is done by replacing the liquid ballast with the same amount by weight of solid ballast.

In cases where liquid ballast is inevitable, the procedure can be followed below:

AVERAGE WEIGHT DISTRIBUTION

IT IS RECOMMENDED TO CHECK WITH THE MANUFACTURER OF THE EQUIPMENT.

| MODELO DEL TRACTOR | EJE DEL TRACTOR | EQUIPO ARRASTRE | SEMIMONTADO |

| 4X2 | DELANTERO | 25% | 30% |

| 4X2 | TRASERO | 75% | 70% |

| MODELO DEL TRACTOR | EJE DEL TRACTOR | EQUIPO DE ARRASTRE | SEMIMONTADO |

| 4X2 MFWD | DELANTERO | 35% | 35% |

| 4X4 | TRASERO | 65% | 65% |

PROCEDURE FOR USE OF THE LIQUID LASTRE

• Obey the recommended procedures for mounting the tire in the ring (ALAPA).

• Mount your tire on the tractor according to the recommended procedures (ALAPA).

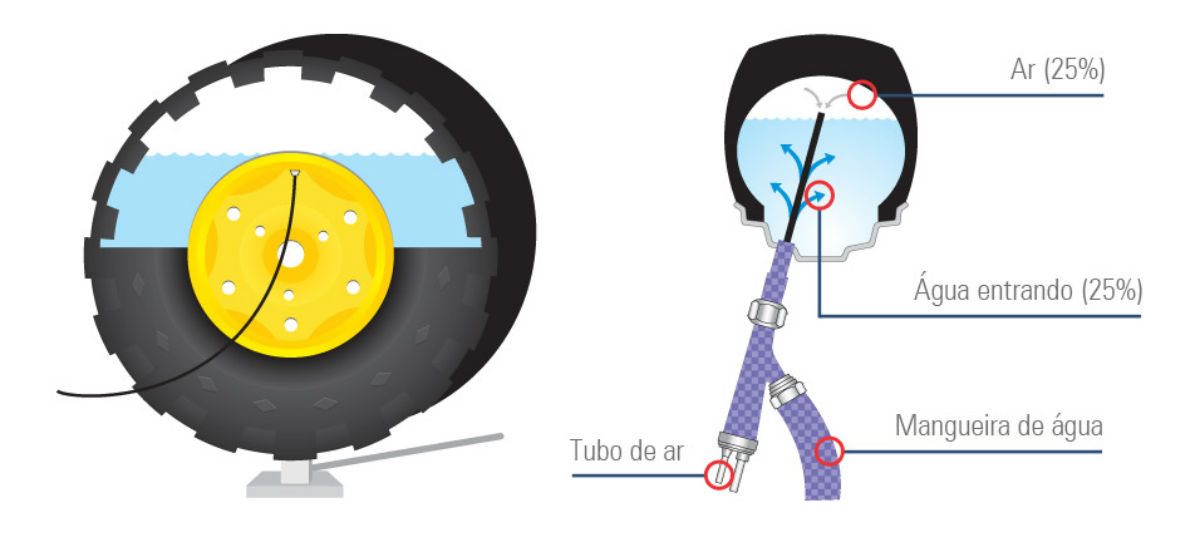

• The ballast operation with water must be carried out with the wheel mounted on the tractor and lifted off the ground.

• Turn the wheel until the valve remains in the upper position of 12:00 hours.

• Remove the valve core.

• Fill the tire with water using a common hose attached to an adapter for this purpose.

• When the filling reaches the level of the valve (75% of the tire), it will start a leakage of the excess through the adapter.

• Stop the filling operation and reposition the valve core.

• Inflate the tire with one or two pounds at more than the recommended pressure for operation, with the valve still in the upper position.

• Turn the wheel until the valve remains in the lower position of 6:00 hours and reposition on the ground.

• Calibrate the tire with the recommended pressure.

• Do not forget the valve cover.

MAXIMUM RECOMMENDED LIQUID VOLUME

Diagonal tires

• Take into account a maximum of 75% of the volume of the tire to avoid eliminating its flexural and damping properties.

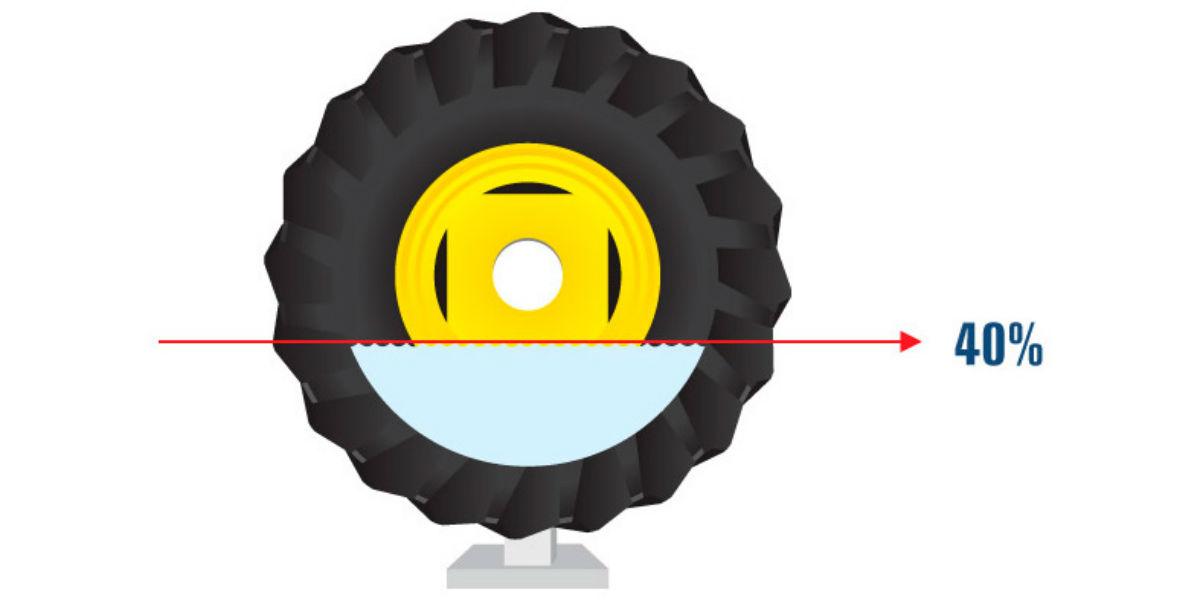

Radial Tires

• Only in special cases and with the manufacturer's recommendation, fill up to 40% of the volume of the tire.

• Liquid ballast is recommended whenever possible by the weight equivalent in solid ballast.

Leave your comment